UHMWPE is a fiber spun from polyethylene with a relative molecular mass of 1 million to 5 million. It is currently the world’s strongest and lightest fiber. Its strength is 15 times higher than that of steel wire. Very light, up to 40% lighter than materials such as aramid.

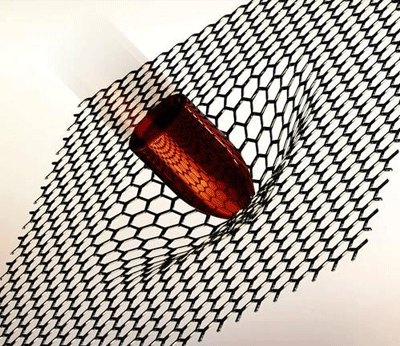

In terms of national defense equipment, because the fiber has good impact resistance and greater energy absorption, it can be made into protective clothing, helmets, and bulletproof materials in the military, such as armored protective panels for helicopters, tanks and ships, and radar Protective shells, missile covers, body armor, stab-resistant vests, shields, parachutes, etc., among which the application of body armor is the most eye-catching.

It has the advantages of lightness and softness, and has now become the main fiber occupying the US bulletproof vest market. In addition, the specific impact load value U/p of the ultra-high molecular weight polyethylene fiber composite material is 10 times that of steel, and more than twice that of glass fiber and aramid. Bulletproof and riot helmets made of fiber-reinforced resin composite materials abroad have become substitutes for steel helmets and aramid-reinforced composite helmets.